Hot-stamping

Metallic foils—gold, silver, or vibrant colors—add a luxurious, eye-catching shine, perfect for premium branding.

Holograms

Elevate visual appeal with dimension and shimmer that draws attention on the shelf.

Selective Varnishing (Matte/Gloss)

The interplay of texture and light—contrasting matte and glossy varnishes deliver a striking tactile and visual experience.

Peel-off Labels

Ideal for promotions, contests, or bonus content. A clean and clever solution that doesn’t require expanding the label size.

Scent Effects

Fragrance-activated labels (think hops, berries, or coffee) add an unexpected multisensory experience consumers love.

Thermal & Fluorescent Effects

Watch your label transform with heat, UV light, or environmental triggers—perfect for bold, creative marketing campaigns.

Embossing

Add texture, depth, and sophistication with precision-pressed finishes.

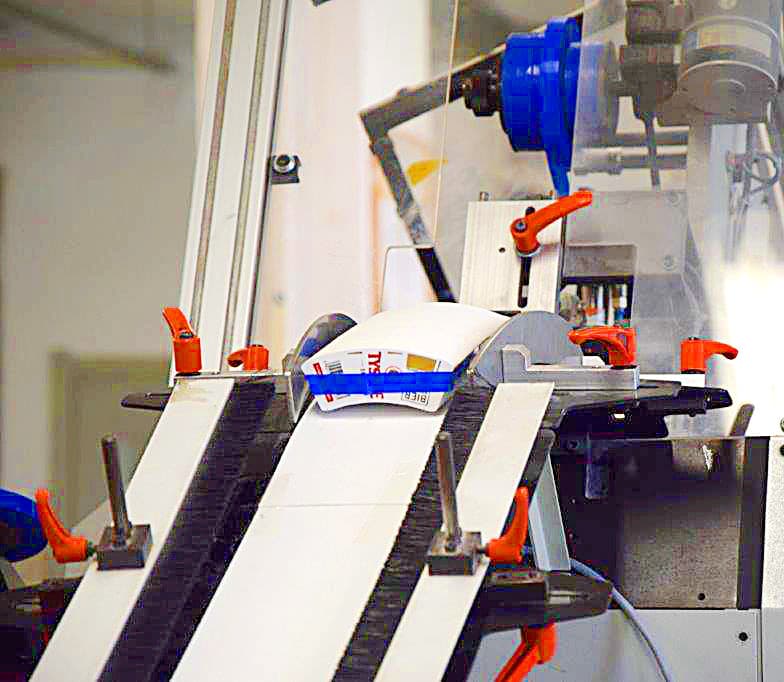

Perforation

Subtle micro-cuts make labels easy to peel—a practical, industry-spanning enhancement.

Label Mixing

Perfect for limited editions or collectible series where each label is unique.